Ergun Software for Bubbling Beds

Heat Transfer

Fluid beds provide excellent performances in heat transfer. The very high heat transfer coefficient (usually above 200 W/m²K) in common fluid beds is one of the major reason for which they are used for exothermic reactions. However, the calculation of "Heat Transfer Coefficient" in fluidized beds, especially at high temperatures that is not always easy. Three phenomena are to be taken into account:

- Gas (bubble) direct heat transfer by convection and conduction

- Solid heat transfer by direct conduction while a layer of gas remains between the tube and contacting particles

- Heat transfer by radiation (for relatively high temperatures only)

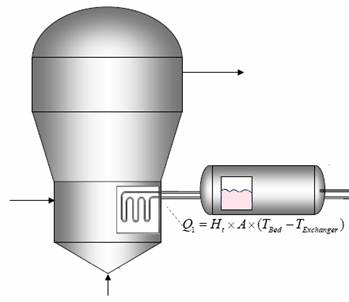

Schematically, the heat transfer phenomenon can be explained by the following figure :

There are a great number of correlations and models proposed in the fluidization literature. At high temperatures three phenomena interfere in the process of heat transfer between an exchanger tube and the gas-solid suspension: "convection", "conduction" and "radiation". On the other hand, fluidization properties (bubble size, bed voidage…) influence strongly the overall heat transfer coefficient. It is always difficult to choose the proper method among the list of different methods.

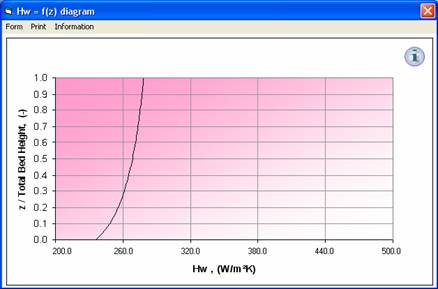

Ergun provides some chosen methods (or correlation) for each case. Results are presented in fully interactive diagrams where the user can study the effect of operating conditions on the designed variable.

Ergun Design Technology

Classical heat exchanger configuration with vapour production

example of results obtained and presented by the program

Links to other pages: Site Map