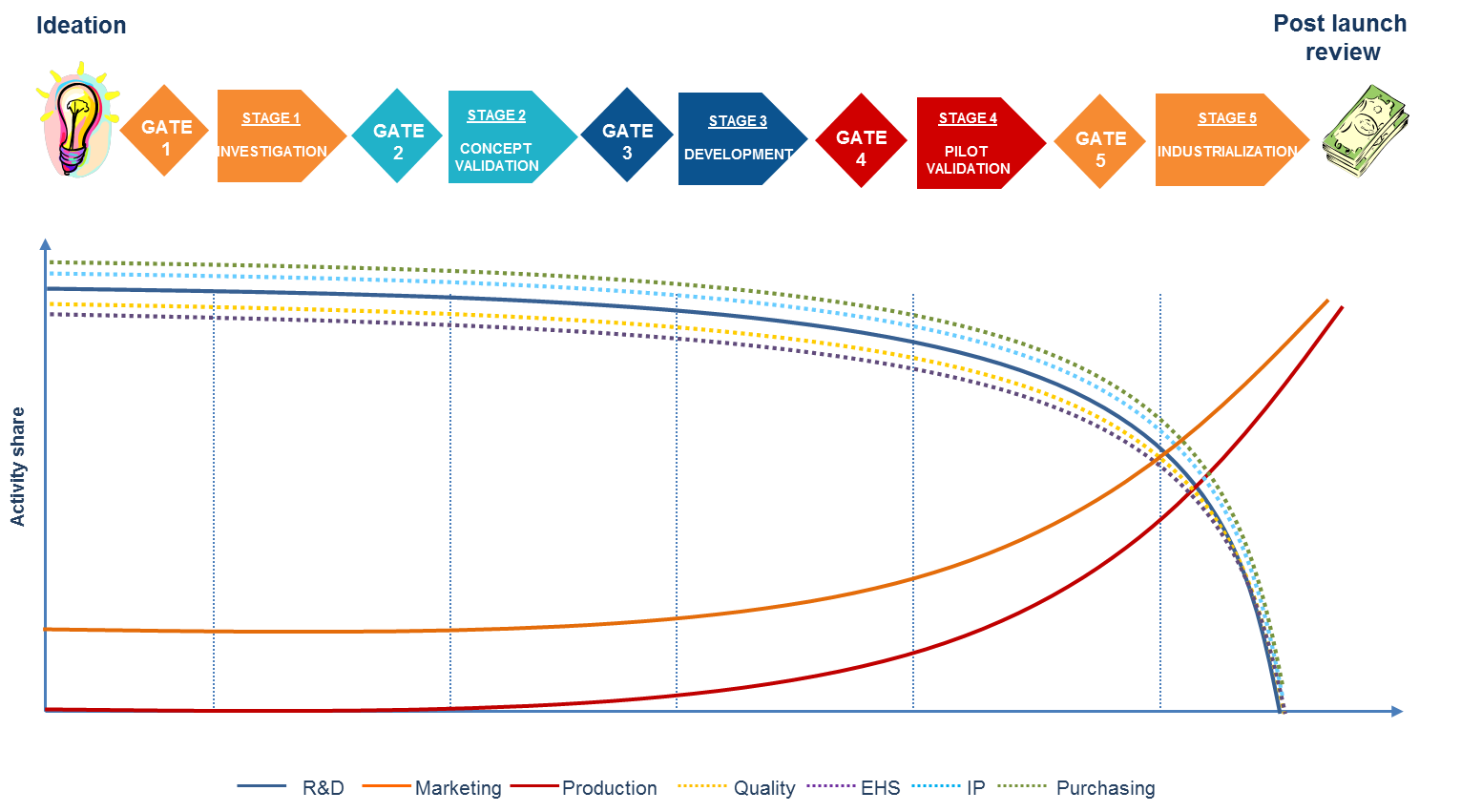

The Stage Gate is roadmap with 5

stages and gates followed by a post launch review:

Gate 1: It is the initial idea screening to

decide if it offers a high potential value in Market

and fits the Business Unit objectives. If the

decision is favorable funding is granted for the

stage 1.

Stage 1: It is the preliminary investigation

to validate the idea and define the objectives of

the project.

Gate 2: It is the feasibility review to

evaluate the requests for the next stage.

Stage 2: It is the concept validation to

validate the idea by carrying a deep marketing and

feasibility analysis.

Gate 3: Authorize funding and resource

commitment for the following stage.

Stage 3: It is the development phase to:

o Produce a working prototype E0

at lab scale.

o Identify process capability.

o Analysis of the technical and

financial trial results.

o Marketing analysis and

business plan confirmation.

Gate 4: To approve the budget required for full

production trials.

Stage 4: It is the pilot validation to:

o Perform full scale trial

o Define the process improvement

o Calculate production costs

o Validate supply capacity and

confirm business plan

Gate 5: To review the results of previous stages

and the projected financial data.

Stage 5: The final stage is the

industrialization which means to implement the full

production run and successfully launch the project.

Following the full Stage Gate Process, a post launch

review is conducted in order to evaluate the

effectiveness of the process and suggest

improvements for future project launches.

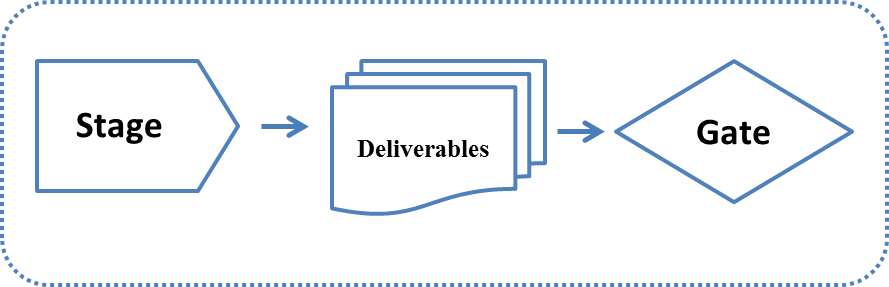

The Stage Gate is cross-functional. It is driven by

R&D, Marketing and Production. The R&D

is supported by different departments including:

Quality, EHS, Patent Service and Purchasing. A

steering committee evaluates the performance of the

project during each gate review. This is a milestone

check and decision point based on the deliverables

of the checklists. The project cannot proceed and go

to the next stage without a “go” ahead decision.

The checklists contain a list of deliverables

to be checked based on the tasks done in the

previous stage.

3.2

Problem

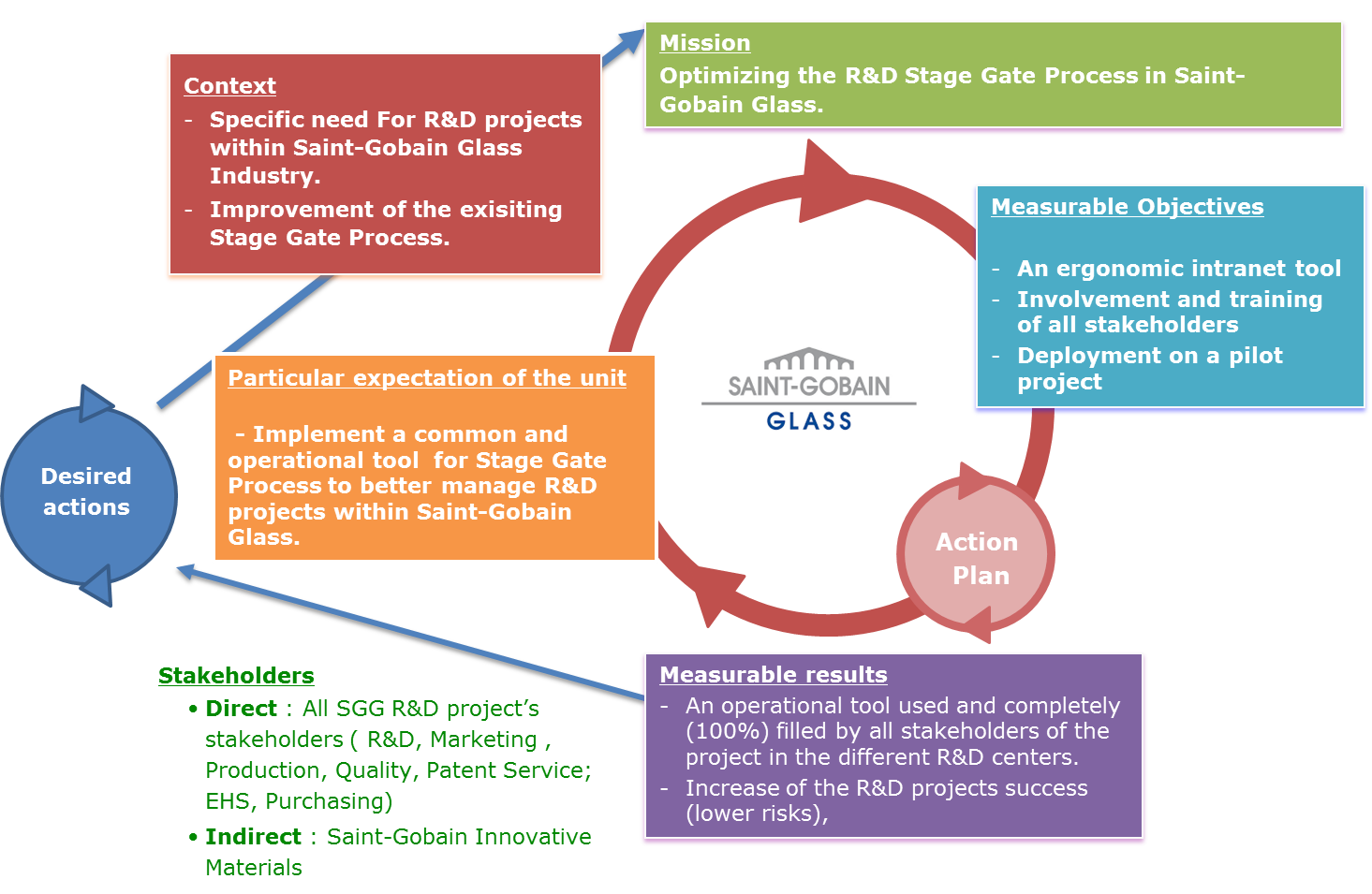

The Stage-Gate process has been initiated to the

culture of Saint-Gobain R&D in order to better

manage innovation. Continuous improvement of the

existing process is at the heart of Saint-Gobain

Glass Industry objectives. The main goal is to

permanently meet the R&D project objectives and

fit the needs of project leaders.

The following table shows the key strengths and

weaknesses of the existing Stage-Gate process. This

helped to better screen the current situation and

identify the main areas of improvement.

+ + +

|

- - -

|

- Strong

documentation basis: Innovator

Handbook

of Saint-Gobain.

- Continuous

improvement. |

- Heavy

gate review checklists

- Many

tools used in the different R&D

centers (gate checklist, Product

Launcher)

- More

than one data base for R&D

projects

- Lack

of training of the project leaders

- Bureaucratic

system (many deliverables,

non-added-value items, many meetings

and committees…) |

Table 1:

Strong and weak points of the existing Stage Gate

Process[8]

Gate review is a critical check point and one of the

weakest area in new product development. In fact,

only 33% of firms have a robust operational Gate

review system [9]. Moreover, only 56 % of project

are successful and meet their sales targets.

The existing gate review in Saint-Gobain Glass is

not fully satisfactory and doesn’t fit the needs of

project leaders. The tool is considered heavy and an

extra work. Neverthless, this extra work if it is

well defined and optimized it is well worth the

effort as it yields to increased success rates,

greater profits and often shorter time to launch in

the market.

3.3 Problem

Solving methodology

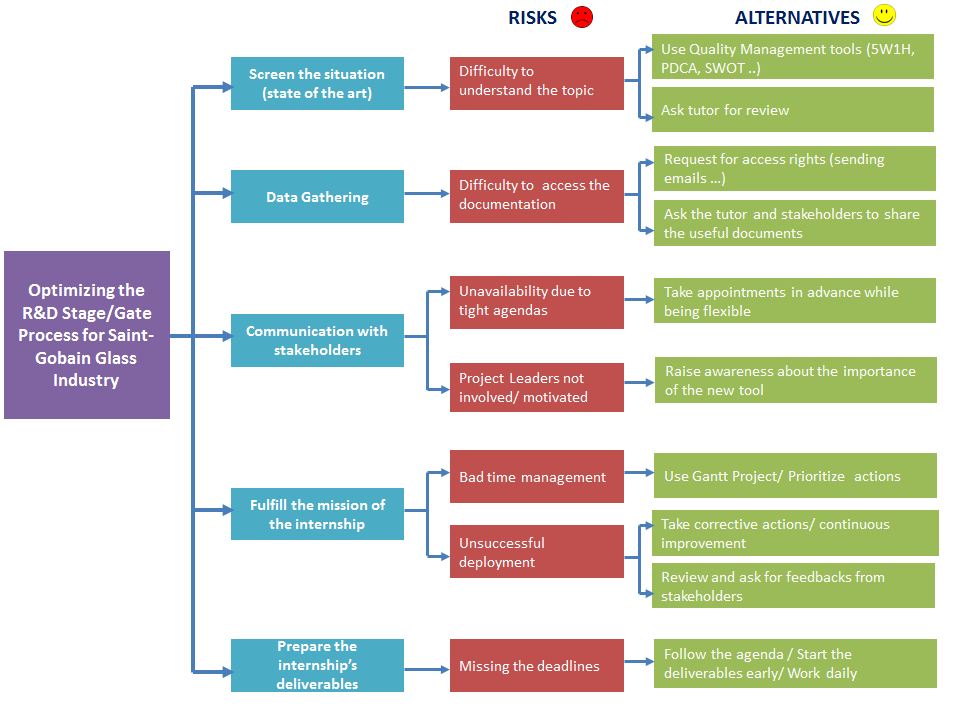

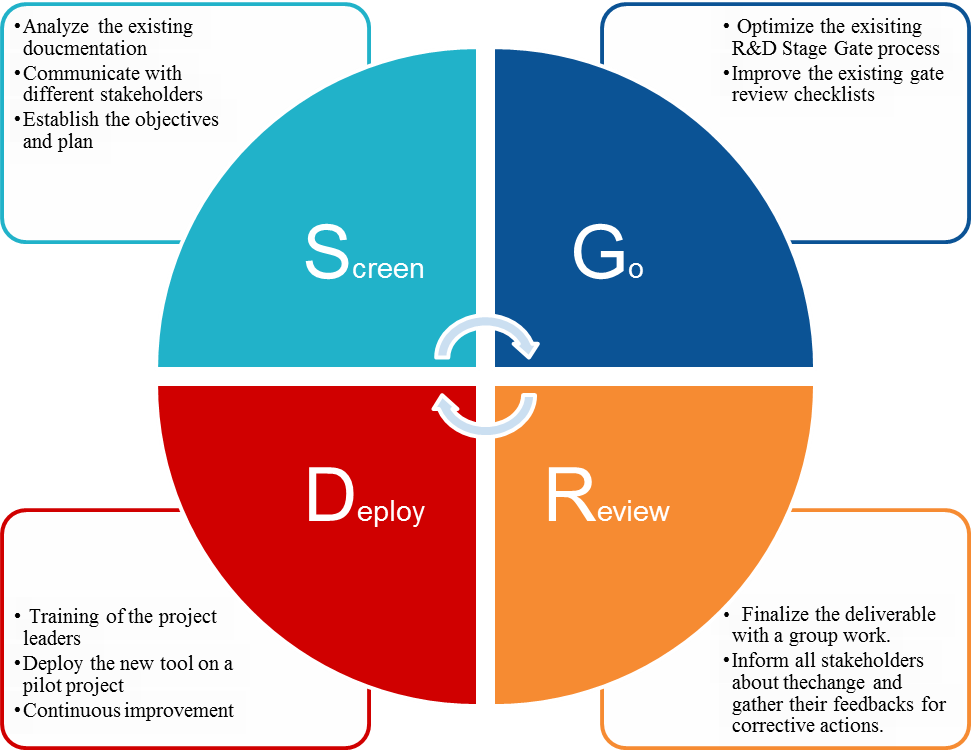

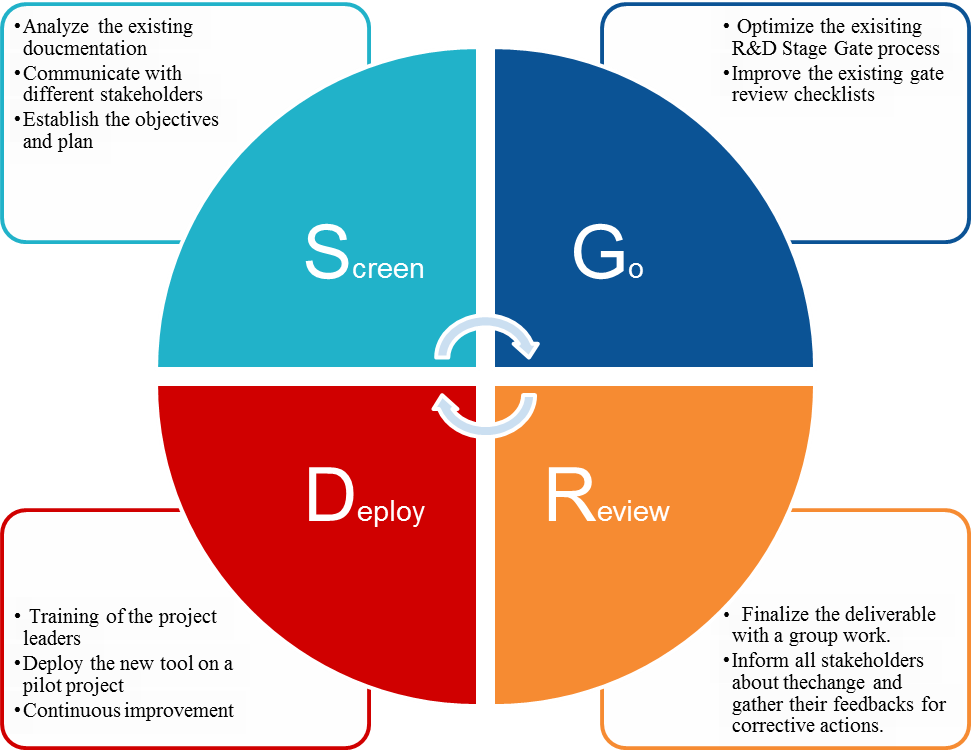

In order to adopt a robust problem solving

methodology a Deming Circle was designed (Figure

12). SGRD refers to Screen, Go, Review and Deploy.

Figure

12

Figure

12 : SGRD Saint-Gobain R&D Deming

wheel [8]

Screen: The first

step was to understand the existing system. The

state of the art analysis is critical since it

helps to identify the main areas of failures and

improvement. Analysis of the existing

documentation and communicating with the

stakeholders were important to do a better

screening. Afterwards, a deep analysis was

conducted on problem identification and the plan

of the action plans.

Go: The DO phase and putting into

practice the tasks planned in the screening

phase. The core project is to improve and

implement a new gate review checklist while

tackling the weak points and failures of the

existing system. Interviewing the stakeholders

mainly the project leaders was the method

adopted.

Review: Upon completion of the GO

phase and once the deliverables are ready, a

checking phase is essential in order to have

feedbacks from stakeholders, identify the

potential problems and take corrective actions

as necessary.

Deploy: The final phase is the deployment

of the new tool on a pilot project. Therefore,

training of project leaders is highly needed to

ensure that they assimilate and know how to

operate it. Continuous improvement of the new

tool is also one of the main tenets of this

work.

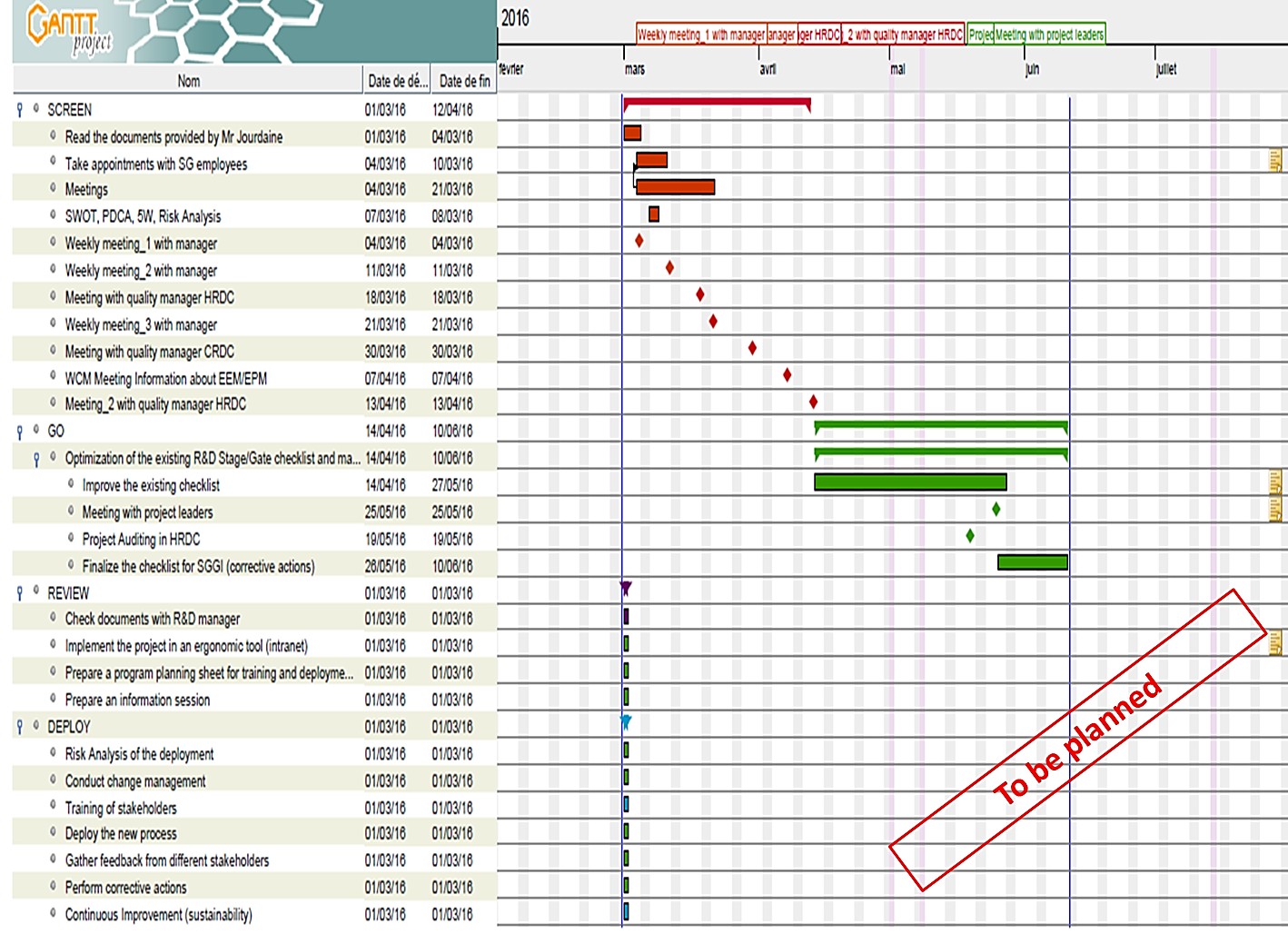

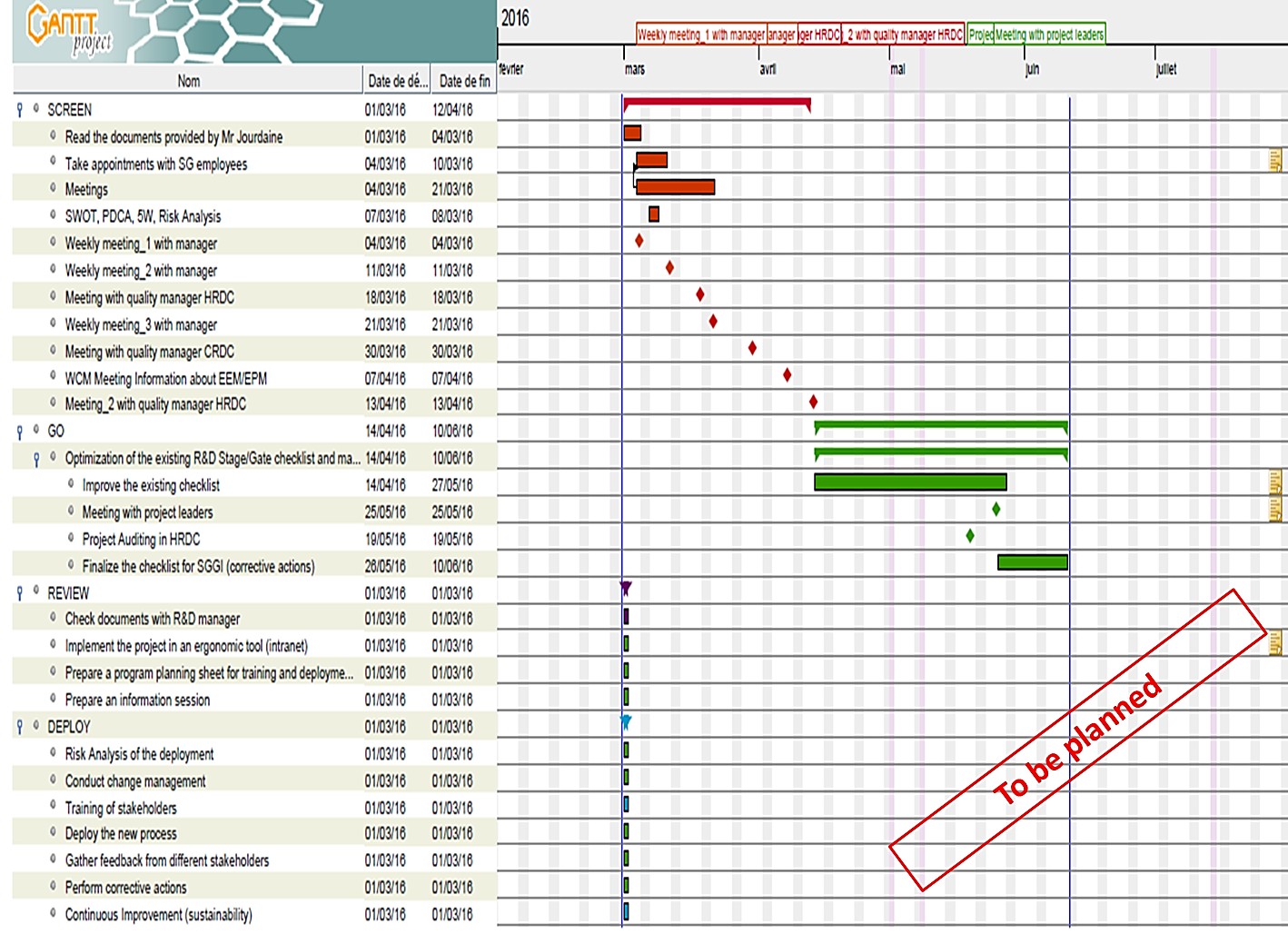

Aligning with the SGRD described previously, a

plan was plotted using Gantt project shown in

Appendix 1.

The main objective was to implement an

integrated, evolving process that builds agile

methods. The new Stage Gate process is not a

lock-step rigid process. It is a tool that helps

to have a better project management system

rather than a heavy project-control mandatory

tool. It is therefore tailored to the needs of

the project.

The main objective was to implement an

integrated, evolving process that builds agile

methods. The new Stage Gate process is not a

lock-step rigid process. It is a tool that helps

to have a better project management system

rather than a heavy project-control mandatory

tool. It is therefore tailored to the needs of

the project.

3.3.1

SCREEN

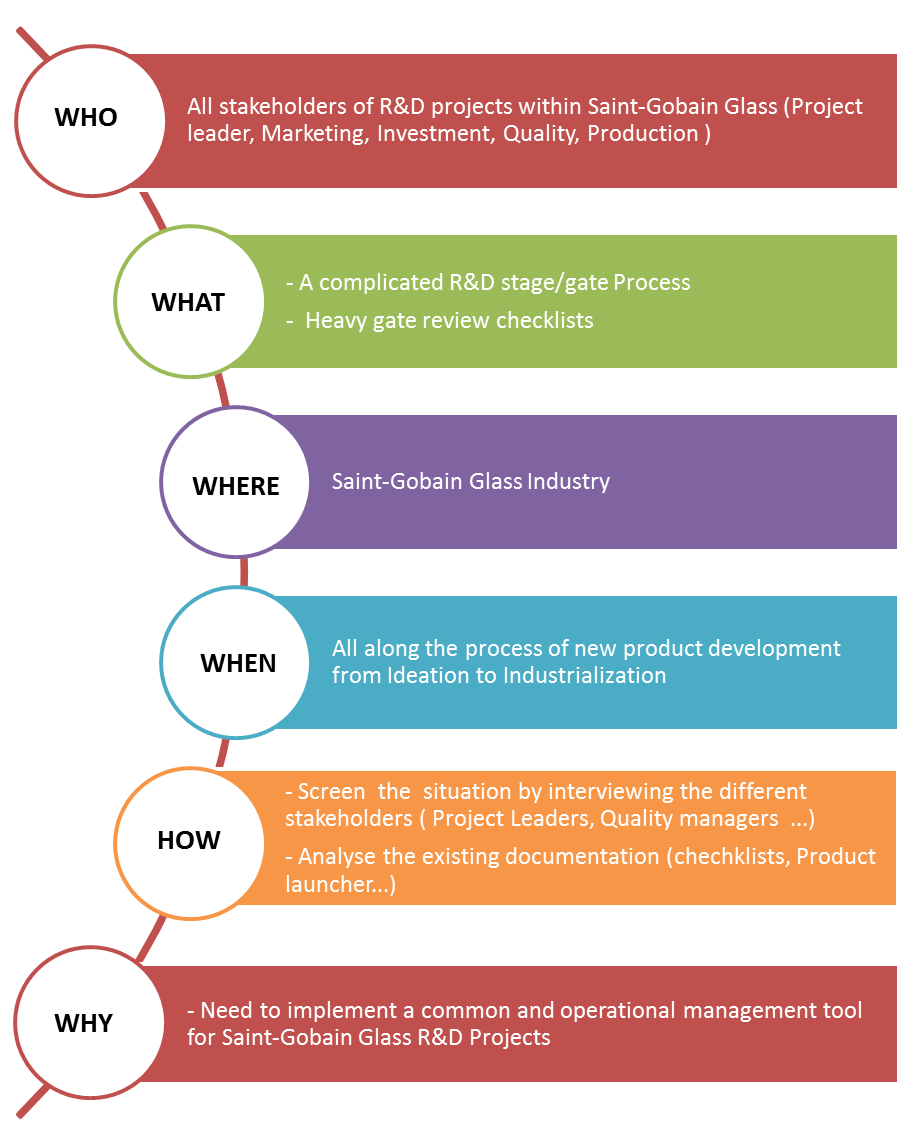

To better screen the situation, analysis of the

existing documentation was essential (Innovator

Handbook, Gate Checklists, Product Launcher,

Gate review presentations …). Moreover,

stakeholders helped me to better understand and

assimilate the situation and provided me with

needed information.

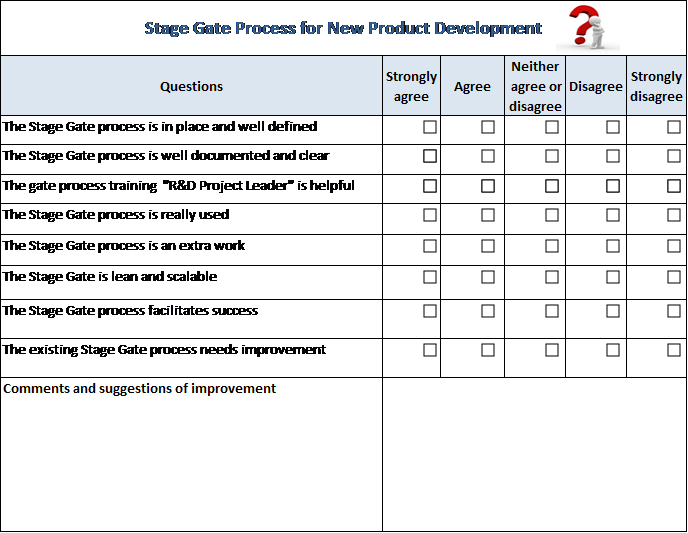

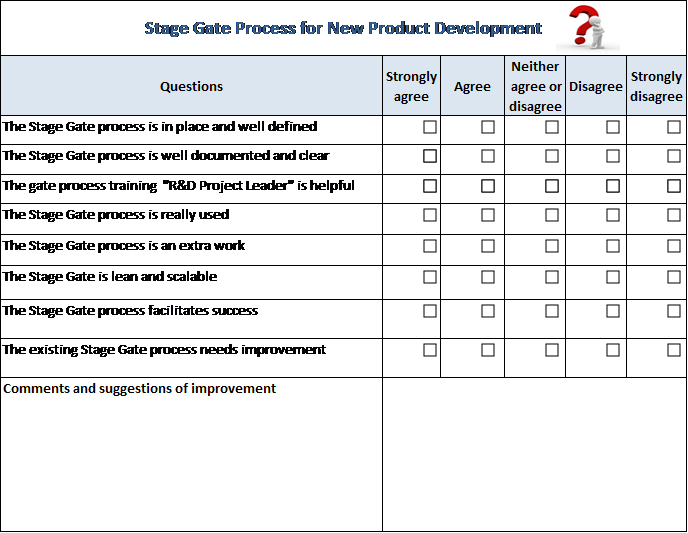

Then a short anonymous questionnaire was

prepared and sent to Project Leaders (Figure

13):

Figure 13

Figure 13 : Questionnaire about the

existing Stage Gate Process [8]

Project Leaders were

reactive and most of them responded to the

questionnaire and gave their opinions and

suggestions of improvement. 100% of the

Project Leaders that answered agreed that

the existing Stage Gate process needs

improvement.

Upon completion of this screening phase a

SWOT analysis was designed (Figure 14) to

identify the internal and external factors

that affects the fulfillment of the mission.

: SWOT Analysis [8]

This framework helped to

uncover the strengths/opportunities to

exploit and weaknesses/threats to face and

know how to avoid and eliminate.

3.3.2

Go

Improving the existing Stage Gate Process

required a significant communication with

stakeholders and auditing R&D project.

3.3.2.1

Communication with stakeholders

The method adopted was agile:

interviewing and meeting the stakeholders

was the key success to implement the new

gate review tool. In fact, effective

communication keeps the stakeholders engaged

and motivated. It has also played a crucial

role to identify the root causes of the

existing system’s weaknesses.

Gathering constructive feedbacks from

stakeholders helped to implement the

necessary corrective actions and make a

suitable and operational common tool for the

Stage Gate process.

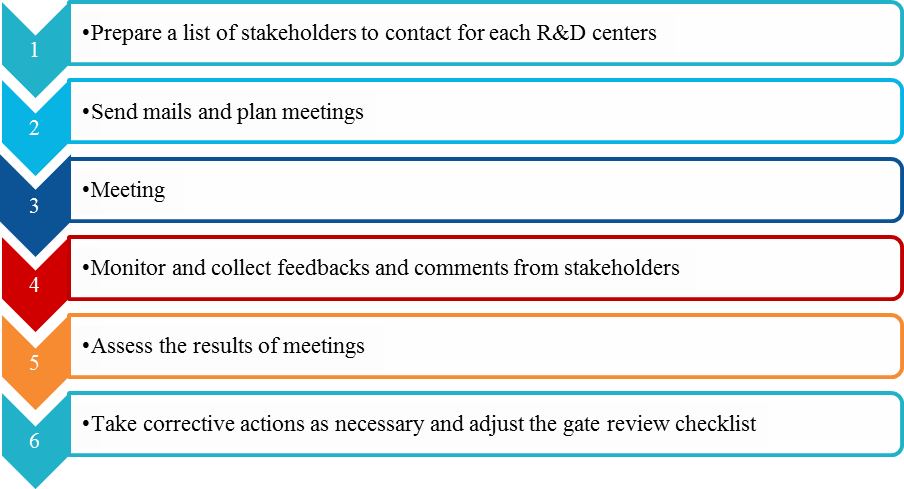

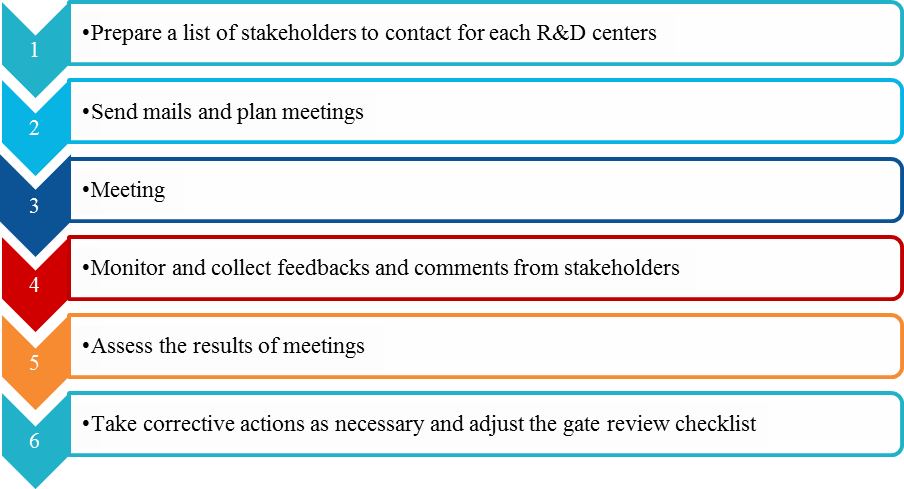

The following flowchart (Figure 15) shows

the steps taken to hold the interviews with

the stakeholders.

Figure

15

Figure

15 : How to bridge the communication

gap ? [8]

he stakeholders involved mainly project leaders

(experienced and new), Portfolio managers and

Quality manager

A checklist questionnaire for the meeting was

prepared in advance with open-ended questions as

follow:

1. First feedback

about the proposal of the gate checklist’s new

version (Format, sections …)?

2. Is there any

incomprehensible question?

3. Do you consider

this question mandatory or optional?

4. Is there any missed

question at this stage that is killer to the

project?

5. Do you suggest any

other areas of improvement?

Upon response to these questions, corrective actions

are undertaken to better fit the stakeholders’

needs.

The human factor played a crucial role to make a

better adapted Gate Checklists. Meetings were

undertaken in 3 different R&D centers: SGR, CRDC

and HRDC.

3.3.2.2

Project Audit

In order to support the feedbacks gathered from the

different interviews, a project audit was planned

and conducted on a pilot project in the Research

Center of Germany HRDC.

The evaluation of R&D projects within

Saint-Gobain is based on two criterias:

- Evaluation

of the steering committee

- Rating of the

project audit

The project audit was conducted by a qualified

auditor internal to the organization: the head of

quality management in the R&D center of Germany.

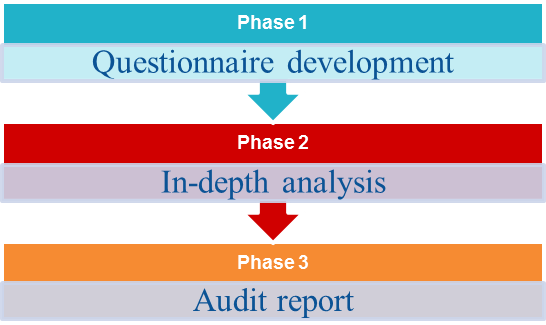

The audit is performed in 3 phases and usually

occurs after the stage 3 of the Stage Gate process:

Phase 1: Questionnaire development (Appendix

5)

This phase is focused on interviewing the

project leader to evaluate the performance of his

work and ensure that the major project keys points /

needs are met.

The audit checklist is sent to the project manager

and other stakeholders (audited entity) in advance

so they get informed about the questions.

The interview helps the auditor to get deeper

insights into the interviewee’s answers and

comments.

The checklist questionnaire reflects the project’s

successes, failures, challenges and missed

opportunities.

Phase 2: In-depth analysis

This phase is mainly based on assessing the issues

to get the root causes of the problem. Thus, the

auditor reviews all the deliverables/documentation

of the project according to the checklist

questionnaire.

Following this, the lessons learned and action plans

are identified in order to improve the performance

the project .

The improvement program is monitored by the audited

entity and must be completed within duration of 90

days. The auditor monitors the implementation.

Phase 3: Audit Report

This phase consists of collecting the information

and consolidating the documentation review.Then the

auditor creates and finalizes the audit report and

recommendations.

Another audit has to be planned to review the

corrective actions and action plans taken by the

project leaders and make sure that the deviations

have been corrected.

The main objective of a project audit is to identify

the action plans that can help improve the

performance and yield of a project as well as to

improve future projects. Therefore, project audit is

highly beneficial and recommended for every

organization.

The project audit helped to better assess the weak

points of the existing Stage Gate system.

On the basis of the communication with stakeholders

and project audit action plans have been taken. A

new gate review checklist have been implemented

which will be transferred in an ergonomic interface

(in progress). The planning of the review and

deployment phase is ongoing.

3.4

Results and perspectives

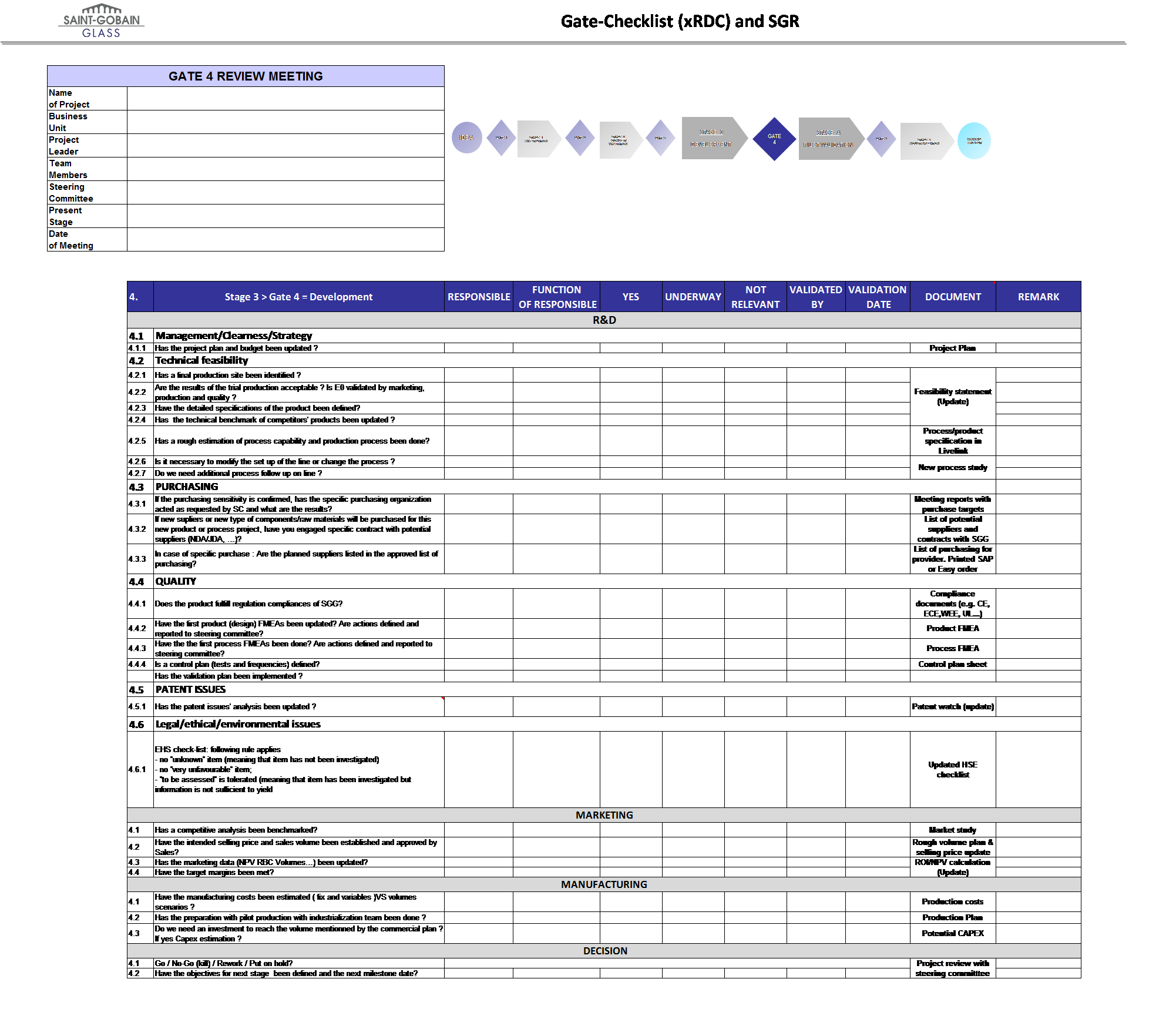

The main modification and improvement made are shown

in the following table:

Before |

After |

- 2

tools of gate review: Gate checklist

(excel sheets), Product Launcher

(intranet). |

- One common tool: Intranet for the

whole process from ideation to

Industrialization. |

- Heavy

tools, Many questions, redundant

questions, some poorly phrased

questions |

- Ergonomic facilitator tool

(Intranet) for the Stage-Gate process,

streamlined checklists, focused

questions and easy to understand.

- 4 sections:

R&D to be filled by the

R&D project leader.

MARKETING to be filled by the

Marketing responsible.

PRODUCTION to be filled by the

WCM responsible.

DECISION to be filled by the

Steering Committee. |

- Many

deliverables (too much paperwork) |

- Fewer deliverables (only the

project’s killers) |

- Problems

using the tool

- Project

leaders are left on their own and

gathering project data and managing

documents on their way. |

- Strengthened training of the project

leaders to the new tool. |

- Project

leaders not very involved and

motivated. |

- Raising awareness about the

importance of the new tool to better

manage projects and involvement of all

project leaders from the different

R&D centers.

- Informing and involving all project

leaders from the different centers. |

- Templates

for deliverables proper to HRDC and

CRDC

Templates do not exist

for other R&D centers |

- Common templates for deliverables to

be used by all the R&D centers

within SGG

(useful guide to help

structure the bare essential

information) |

- The

gate checklists are filled by the

Project leader |

- The new tool is filled by all

stakeholders |

Table

2: Comparison table before and after

optimization [8]

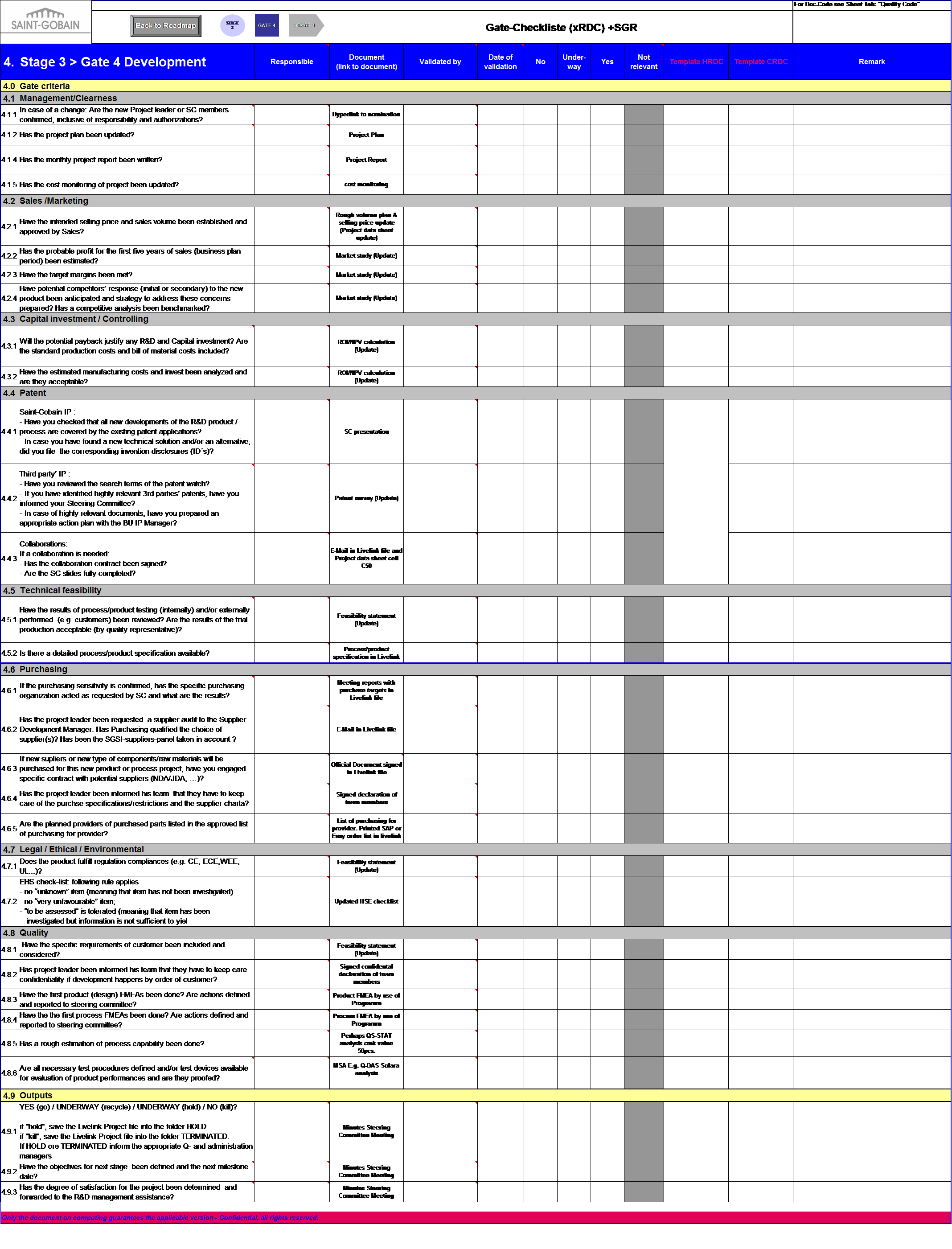

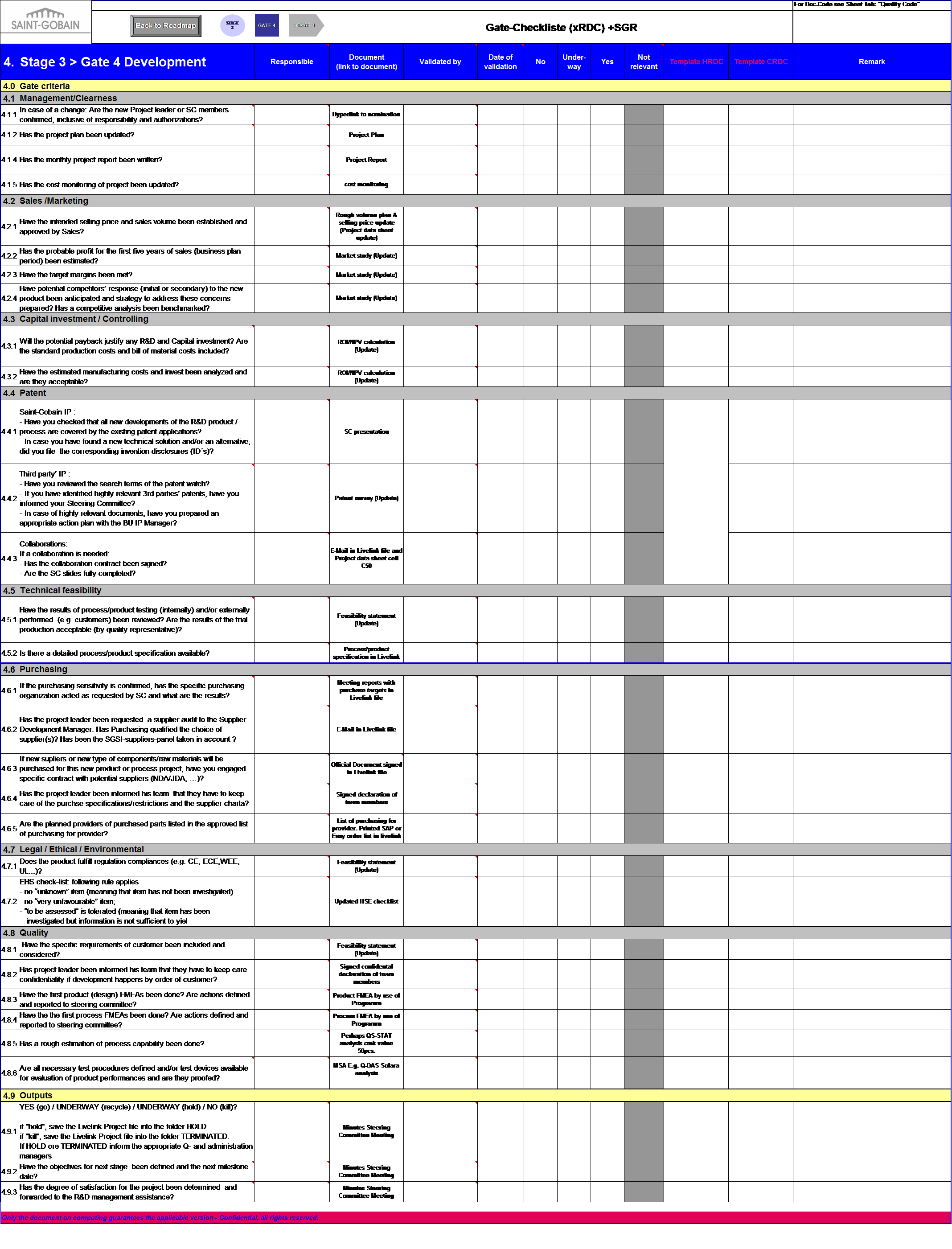

A sample of the new gate checklist is presented in

Appendix 4. The objective of this improvement is the

creation of a well-defined common process.

This new version of the checklist will be finalized

and validated during a meeting with a working group

composed of the quality managers of the different

R&D centers.

The action plans of this meeting:

• Discuss the new version of the

checklists

• Corrective actions

• Plan the release of the final

new version to the stakeholders

• Plan the training of

stakeholders

• Discuss the integration of the

WCM pillar in the Stage Gate Process

• Deployment on a project

• Transfer the checklists in an

ergonomic interface

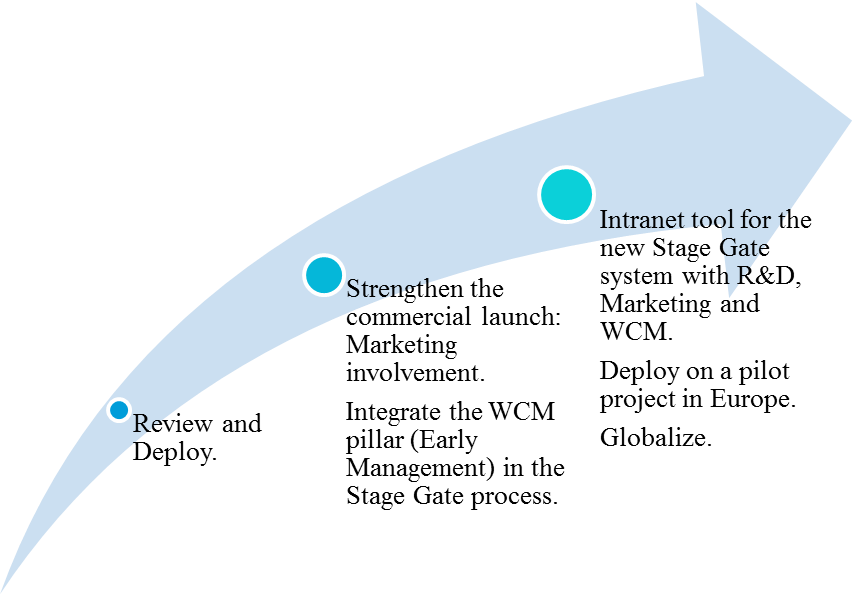

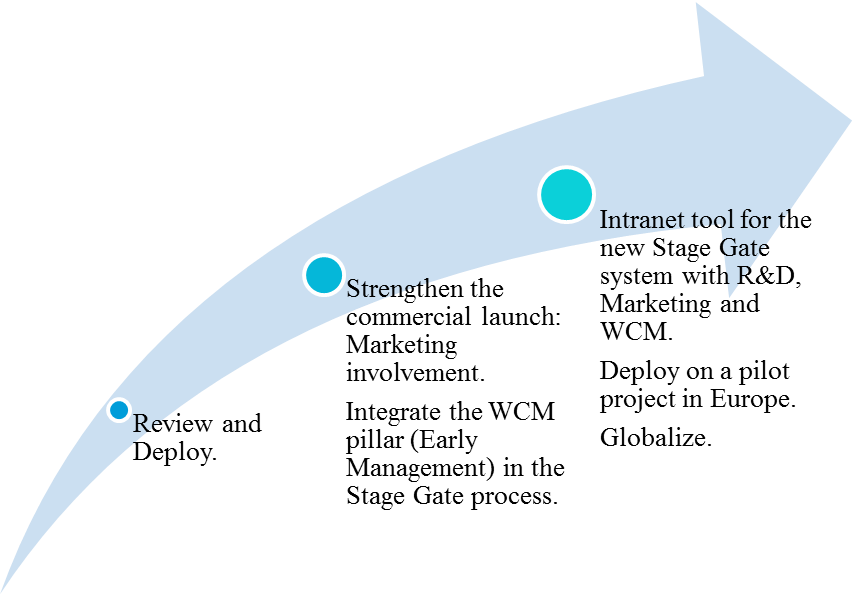

At this point of the mission the two phases of the

SGRD were fulfilled successfully: SCREEN and GO.

The perspectives of this project are described in

Figure 16:

Figure

16: Perspectives of the project [8]

CONCLUSION

This thesis outlines the details

of the Stage Gate process for new product

development. It has tackled a challenge within

one of the most innovative companies, an

initiative to improve its existing system. A new

agile approach has therefore been built approach

to manage projects with all R&D centers of

Saint-Gobain Glass.

The method adopted was agile based mainly on

engaging the key stakeholders to solicit their

inputs and feedbacks for a better change

management.

As mid-term vision, Saint-Gobain Glass plan to

foster the marketing involvement in the Stage

Gate process and integrate the Lean

Manufacturing pillar :” Early Management”

at the end of this process.

As long term vision, Saint-Gobain Glass will

implement the tool for the new Stage Gate

process in an ergonomic intranet and deploy this

on a pilot project to finally achieve its

objective which is putting in place an

operational and common tool for all R&D

centers within Saint-Gobain Glass.

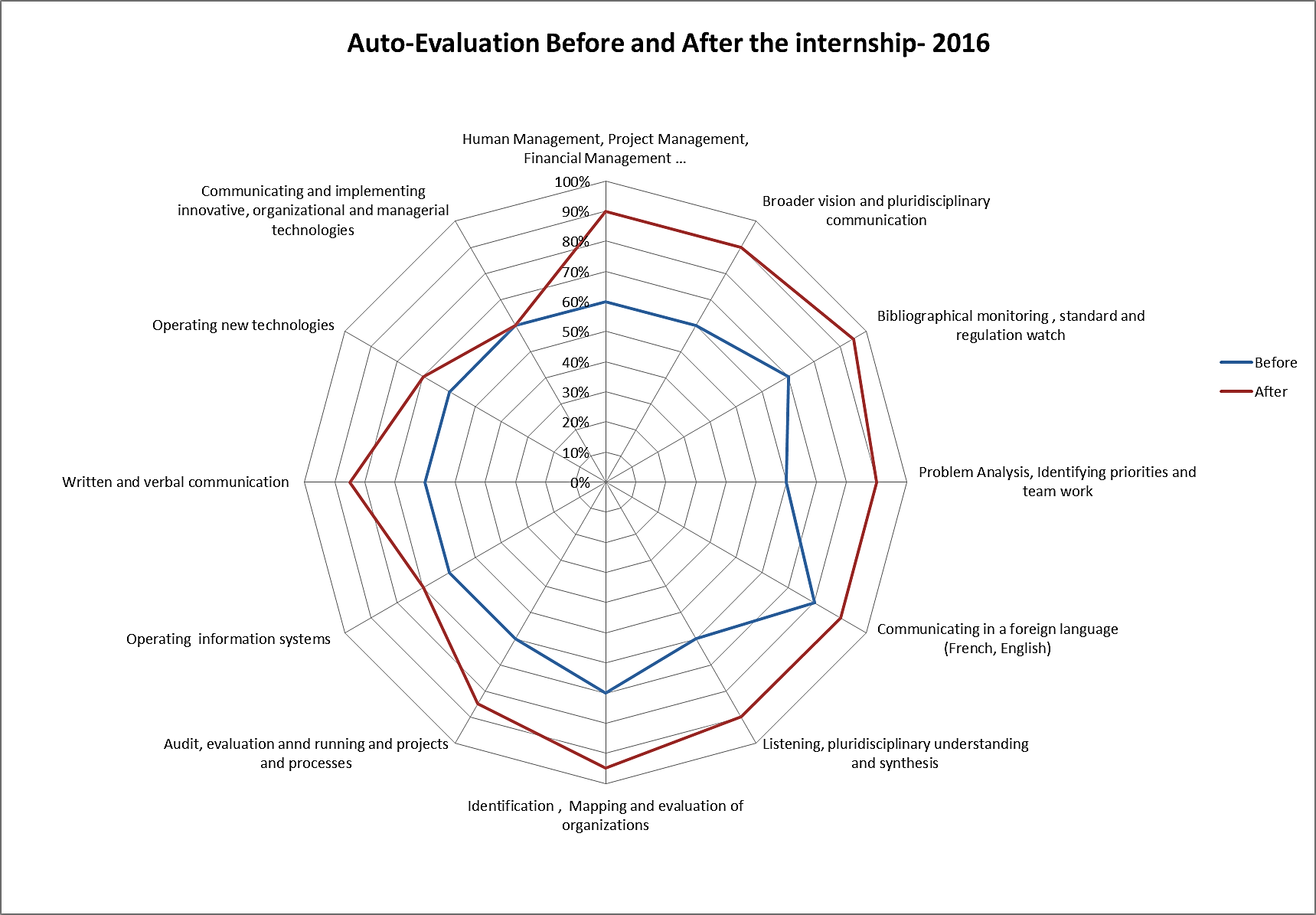

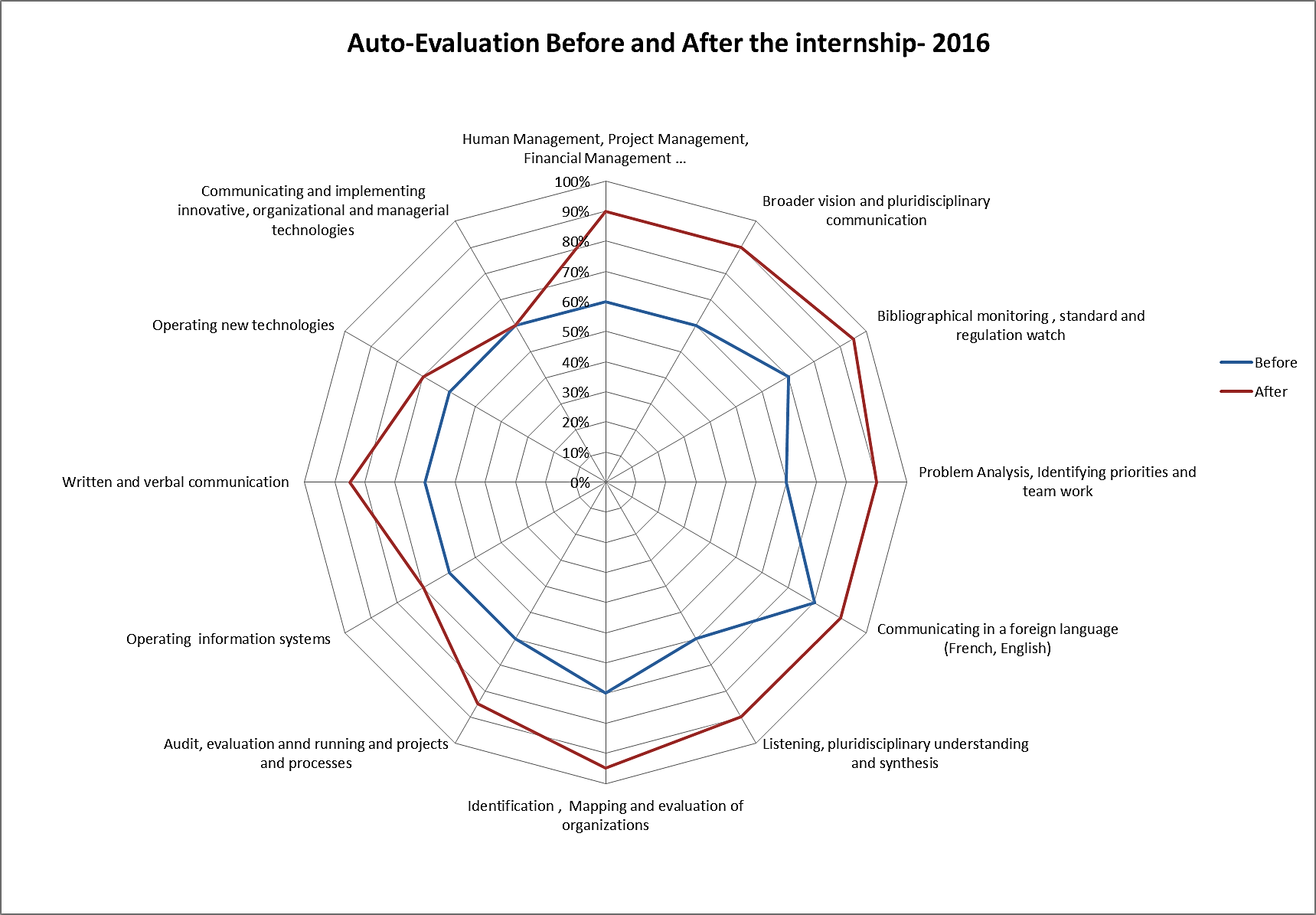

Upon completion of the internship I have

acquired skills at the interpersonal and

professional level (Appendix 2):

- Improvement of

communication skills (French and English

skills)

- Increase of autonomy

- Project management

- Autonomy

- Self-control capacity

- Confidence

- Put in practice the

Quality tools

- Keys points to manage

R&D projects (technical vocabulary …)

It was no doubt a valuable experience which

allowed me to discover new horizons. My previous

professional experiences were mainly focused in

laboratories and thanks to my internship within

Saint-Gobain I have learned what are beyond

laboratories and what is the purpose of Research

and Development and what comes next: A whole

step by step process. I therefore have learned

the methodology of conducting R&D projects

and their key elements.

The mission assigned was challenging. I had to

and implement a tool for 8 R&D centers of

Saint-Gobain Glass Industry. To fulfill this, I

had to coordinate with employees at every layer

mainly project leaders from different centers

and countries. I had to make sure that all

stakeholders are engaged and well informed about

the change.

Thanks to this, I have learned how to conduct a

good project management. Moreover, I

strengthened my leadership skills and

professional communication.

As a graduate in Industrial Chemistry with

double major in Quality Management, my interest

in working in innovative companies became

stronger. Developing my technical and management

skills for a better innovation is now at the

heart of my professional objectives.

BIBLIOGRAPHY

[1]

« Intranet Saint-Gobain-Innovative Materials

». [En ligne]. Disponible sur:

http://portal.saint-gobain.com/web/innovativematerials.

[Consulté le: 03-avr-2016].

[2] R. G. Cooper, S. J.

Edgett, et E. J. Kleinschmidt, « Optimizing

the stage-gate process: What best-practice

companies do-I - ProQuest ».

[3] « About Saint-Gobain

», Saint-Gobain. [En ligne]. Disponible sur:

https://www.saint-gobain.com/en/group/about-saint-gobain.

[Consulté le: 22-mars-2016].

[4] « Saint-Gobain

Presentation ». [En ligne]. Disponible sur:

http://portal.saint-gobain.com/web/communication/sgpresentation.

[Consulté le: 25-mars-2016].

[5] « Présentation Groupe

Saint-Gobain », Saint-Gobain. [En ligne].

Disponible sur:

https://www.saint-gobain.com/en/group.

[Consulté le: 24-mars-2016].

[6] « Portail Saint-Gobain

R&D ». [En ligne]. Disponible sur:

http://portal.saint-gobain.com/web/rd.

[Consulté le: 10-avr-2016].

[7] Compagnie de

Saint-Gobain, Innovator Handbook. 2009.

[8] E. Ben Jemia, «

Optimizing the R&D Stage Gate Process

for Saint-Gobain Glass », Université de

Technologie de Compiègne, Mémoire

d’Intelligence Méthodologique du projet

d’intégration,

https://www.utc.fr/master-qualite, puis «

Travaux » « Qualité-Management » réf n°344,

juin 2016.

[9] R. G. Cooper, S. J.

Edgett, et E. J. Kleinschmidt, « New product

Development Best Practices Study : What

distinguishes the TOP Performers », 2002b.

APPENDIX

Appendix 1: Gantt Project

planning for the internship

Appendix

2: Auto Evaluation before and after

the internship

Appendix 3:

Sample of the existant gate checklist

(excel format)

Appendix 4:

Sample of the new gate checklist ( Gate 4)

(excel format)