Real time prediction of capsule dynamics in microchannels: Method

Introduction

Microcapsules are liquid droplets enclosed within a thin elastic membrane. They are current in nature (red blood cells, bacteria, phospholipidic vesicles) and in various industrial applications (biotechnology, pharmacology, cosmetics, food industry). The membrane plays a key role, as it protects and transports the encapsulated active substances and controls the delivery.

Once placed in an external flow, the microcapsules are subjected to dynamical loading conditions, which lead to their deformation. Identifying the mechanical properties of the capsule membrane remains challenging today and is achieved through inverse analysis by comparing experimental results with numerical simulations.

(b)

(b)

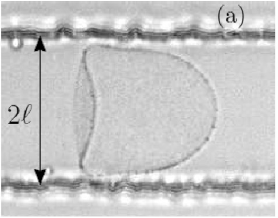

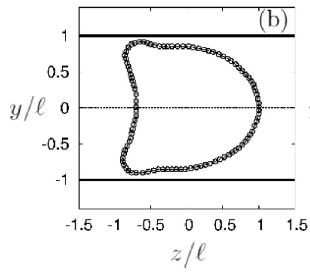

Figure 1: (a) Microphotograph of a capsule flowing in a microfluidic channel. (b) Experimental (dotted line) and numerical (continuous line) profiles superposition (Hu et al. 2013).

Fluid-Structure Interaction resolution

A microcapsule flowing through a microfluidic channel is simulated using a three-dimensional fluid-structure interactions (FSI) model that is built by coupling a boundary integral method for the internal and external Stokes flows with a finite element method for the capsule deformation, the capsule wall being treated as a bidimensional hyperelastic membrane (Walter et al. 2010, Barthès-Biesel et al. 2010).

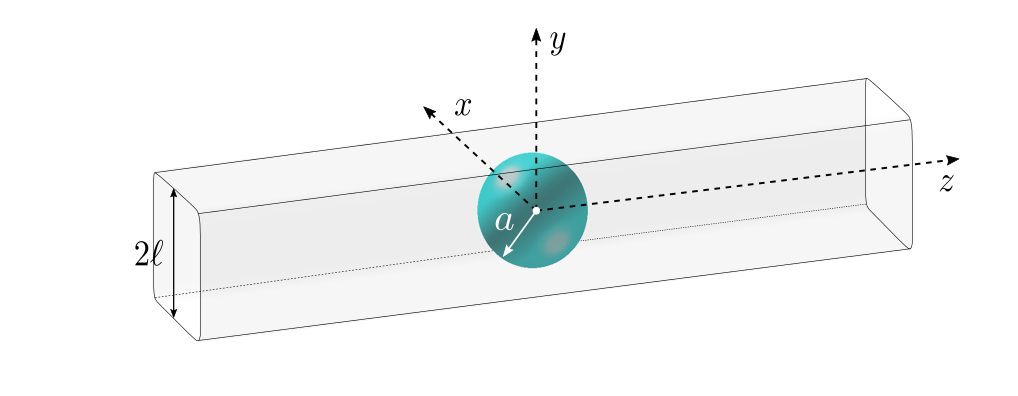

Let a spherical capsule of a radius a be placed freely in a three-dimensional microfluidic channel with a square cross-section of side l (Figure 2). The capsule and the channel are filled by incompressible Newtonian liquids of the same constant density ρ and viscosity μ. The capsule is enclosed by a thin hyperelastic isotropic membrane of surface shear modulus Gs. Far from the capsule, the velocity profile corresponds to Poiseuille flow with mean velocity V.

Figure 2: 3D illustration of an initially spherical capsule subjected to Poiseuille flow in a square microfluidic channel.

The capsule behavior is governed by two parameters: the capillary number of the capsule Ca= μV/Gs, which is the ratio of the fluid viscous forces to the membrane elastic forces, and the aspect ratio a/l between the initial capsule radius a and the channel half width l. It is also function of the constitutive law that is chosen to represent the membrane behavior. In the following, the membrane law is selected to be the Neo-Hookean law, which was shown to adequately model microcapsules with a cross-linked proteic membrane (Chu et al. 2011 , Hu et al. 2013, Wang et al. 2021).

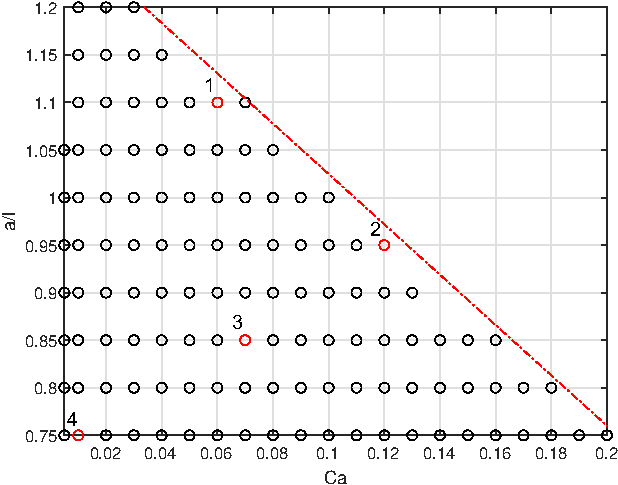

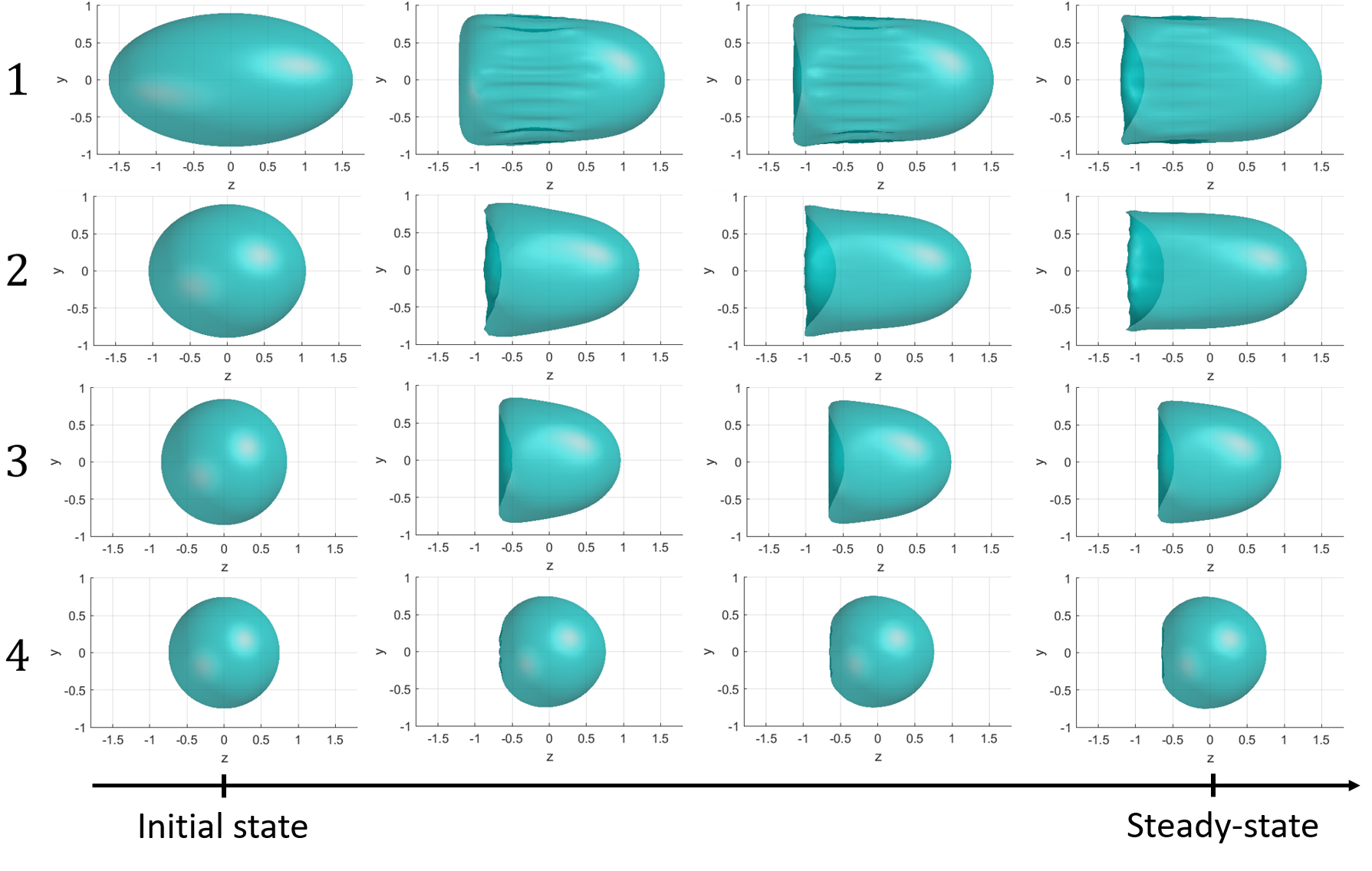

A database containing the results of the three-dimensional simulations is built by varying the values of the parameter couple (Ca, a/l) systematically. Figure 3 shows the region of the parametric space where a Neo-Hookean capsules reaches a steady state. No steady state is found above the dotted red line in figure 3a, the microcapsules exhibiting continuous elongation owing to the strain-softening behavior of the membrane law (Barthès-Biesel 2011).

(b)

(b)

Figure 3: (a) Parametric space containing 118 couples of (Ca, a/l) parameter values, for which a Neo-Hookean capsule reaches a steady state; (b) Time evolution of capsule deformation along the microfluidic channel for the 4 cases shown on the left figure. The capsule is pre-deformed into an ellipsoid when a/l > 0.9.

A new fast-time simulation model

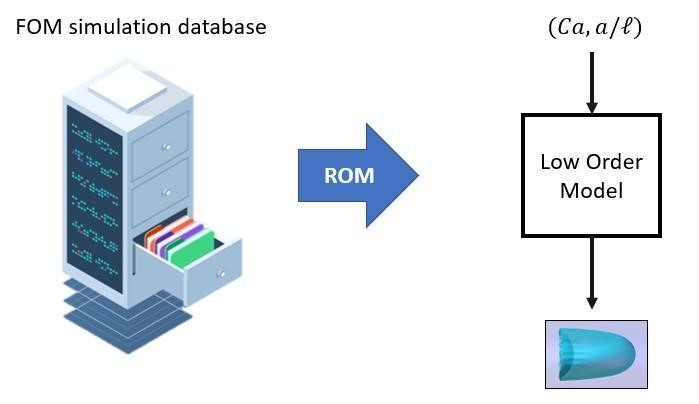

A data-driven Low Order Model is constructed through Model Order Reduction (MOR) techniques using the database of FOM results (see figure 4). The method is detailed in Boubehziz et al. 2021.

Figure 4: Illustration of the Model Order Reduction concept.

It is designed to accurately predict the dynamical evolution of a capsule in a microfluidic channel for any values of the parameter couple (Ca, a/l) in few seconds. The present MATLAB software tool provides the three-dimensional shape of microcapsules at any time and for the values of (Ca, a/l) chosen by the user.

Acknowledgements

This project received funding from the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation program (Grant agreement No. ERC-2017-COG - MultiphysMicroCaps ).

If you find this tool useful in your research, please consider citing our paper:Boubehziz T., Quesada-Granja C., Dupont C., Villon P., De Vuyst F., Salsac A.-V. A Data-Driven Space-Time-Parameter Reduced-Order Model with Manifold Learning for Coupled Problems: Application to Deformable Capsules Flowing in Microchannels. Entropy. 23, 1193 (2021).

References

Barthès-Biesel D. Modeling the motion of capsules in flow. Current Opinion in Colloid & Interface Science 16(1), 3–12 (2011).

Barthès-Biesel D., Walter J., Salsac A.-V. Flow-induced deformation of

artificial capsules. In Computational Hydrodynamics of Capsules and

Biological Cells Taylor & Francis/CRC Press. C. Pozrikidis (ed), 27-62

(2010).

Boubehziz T., Quesada-Granja C., Dupont C., Villon P., De Vuyst F., Salsac A.-V.

A Data-Driven Space-Time-Parameter Reduced-Order Model with Manifold Learning for Coupled Problems: Application to Deformable Capsules Flowing in Microchannels.

Entropy. 23, 1193 (2021).

Chu T.X., Salsac A.-V., Leclerc E., Barthès-Biesel D, Wurtz H., Edwards-Lévy F.

Comparison between measurements of elasticity and free amino group content for

ovalbumin microcapsule membranes: discrimination of the cross-linking

degree. Journal of Colloid and Interface Science. 355, 81-88 (2011).

Hu X.-Q., Sévénié B., Salsac A.-V., Leclerc E., Barthès-Biesel D.

Characterization of membrane properties of capsules flowing in a square-section

microfluidic channel: effects of the membrane constitutive law. Physical Review E.

87, 063008 (2013).

Quesada C., Villon P., Salsac A.-V.

Real-time prediction of the deformation of microcapsules using Proper Orthogonal Decomposition.

Journal of Fluids and Structures. 101, 103193 (2021).

Walter J., Salsac A.-V., Barthès-Biesel D., Le Tallec P.

Coupling of finite

element and boundary integral methods for a capsule in a Stokes flow.

International Journal for Numerical Methods in Engineering. 83: 829-850 (2010).

Wang X.-Y., Merlo A., Dupont C., Salsac A.-V., Barthès-Biesel D.

A microfluidic methodology to identify the mechanical properties of capsules: comparison with a microrheometric approach.

Flow. 1, E8 (2021).