Capsules and microfluidics

Capsule fabrication

We have worked on different techniques of

fabrication of millimetric and micrometric capsules.

Capsules are usually produced in two steps, generating droplets at first

through emulsification (via mechanical agitation, extrusion through a nozzle or

porous membrane, etc) and then generating the formation of the membrane through

various chemical processes (polymerization, solvent evaporation, condensation,

etc). Classical techniques used to create emulsions may be mechanical

agitation, extrusion through a nozzle or a porous membrane, etc. Contrary to

the former, which produces droplets with a large dispersion in size, the latter

may provide monodisperse droplets. But nowadays, microfluidic techniques are another technique to produce

emulsions with a well-calibrated droplet.

Among others, we have developed a microfluidic technique to produce microcapsules that are

calibrated in size and mechanical properties (Chu et al. 2013). The

system contains a first step where droplets are produced, followed by a second

one, when the membrane is created through reticulation (the time of

reticulation being a function of the mean velocity of the suspending fluid and

of the length of the channel), and a third one, when the mechanical properties

of the membrane are determined following the method described below (next section).

Mechanical characterization of microcapsules using microfluidic techniques

1. Characterization of the elastic properties of capsules

Very few experimental data existed on the deformability of initially-spherical artificial capsules. If the mechanical properties of capsules of millimetric size can be measured by compression under parallel plates, other techniques such as micropipette aspiration or AFM are the techniques that had so far been used to characterize microcapsules. But all these techniques can only be applied to single capsules. We have developed a new method of characterization in batch that can be applied to an entire capsule population.

b

b

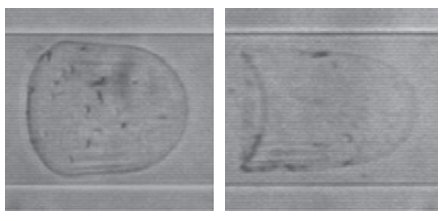

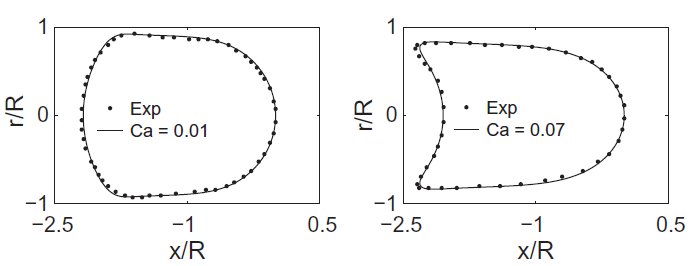

Figure 1: Example of 2 capsules, fabricated at pH 5 with a reticulation time of 5 min, flowing down the microchannel: a/R= 1, v = 1.4 mm/s (left), a/R = 0.95, v = 4.8 mm/s (right). (a) Pictures of the deformed capsule shape. (b) Corresponding superposition of the experimental (dotted line) and numerical (continuous line) profiles (Chu et al. 2011).

The membrane mechanical behavior of liquid filled

microcapsules is obtained using an inverse method. Cross-linked microcapsules

are flowed and deformed into a cylindrical microchannel

of comparable size. We measure simultaneously the deformation and speed of each

capsule through a rapid camera mounted on a microscope (figure 1a). The capsule

deformed shape is compared to predictions obtained numerically when modeling a capsule under the same flow conditions (figure

1b). The unknown shear modulus value corresponds to the best fit. The technique

has been applied to ovalbumin (Chu et al.

2011, Hu et al. 2013) and Human Serum Albumin (Gubspun

et al. 2016) microcapsules.

To enquire about the link between the physico-chemical conditions used during fabrication and the

resulting mechanical properties of the capsules, we have estimated the degree

of reticulation by determining the free amino groups remaining on the

microcapsules after the cross-linking reaction (partnership with Florence

Edwards-Lévy, ICMR, Reims, France) (Chu et al.

2011). We have in parallel characterized the microcapsule populations

fabricated at different reaction pH (5–8) and times (5–30 min) to study

different cross-linking degrees. The capsule shear modulus and the amino groups

are nearly constant with the reaction pH for the capsules fabricated after 5

min of reticulation. The shear modulus increases with the reaction time, while

the NH2 content decreases with it. A global increase in shear modulus with pH

is also observed, together with an unexpected increase in NH2 content. The

study shows that the inverse method is capable of discriminating between

various cross-linking degrees of microcapsules. Moreover, for this type of

microcapsules, the mechanical method appears more reliable than the chemical

one to obtain an estimation of their cross-linking degree.

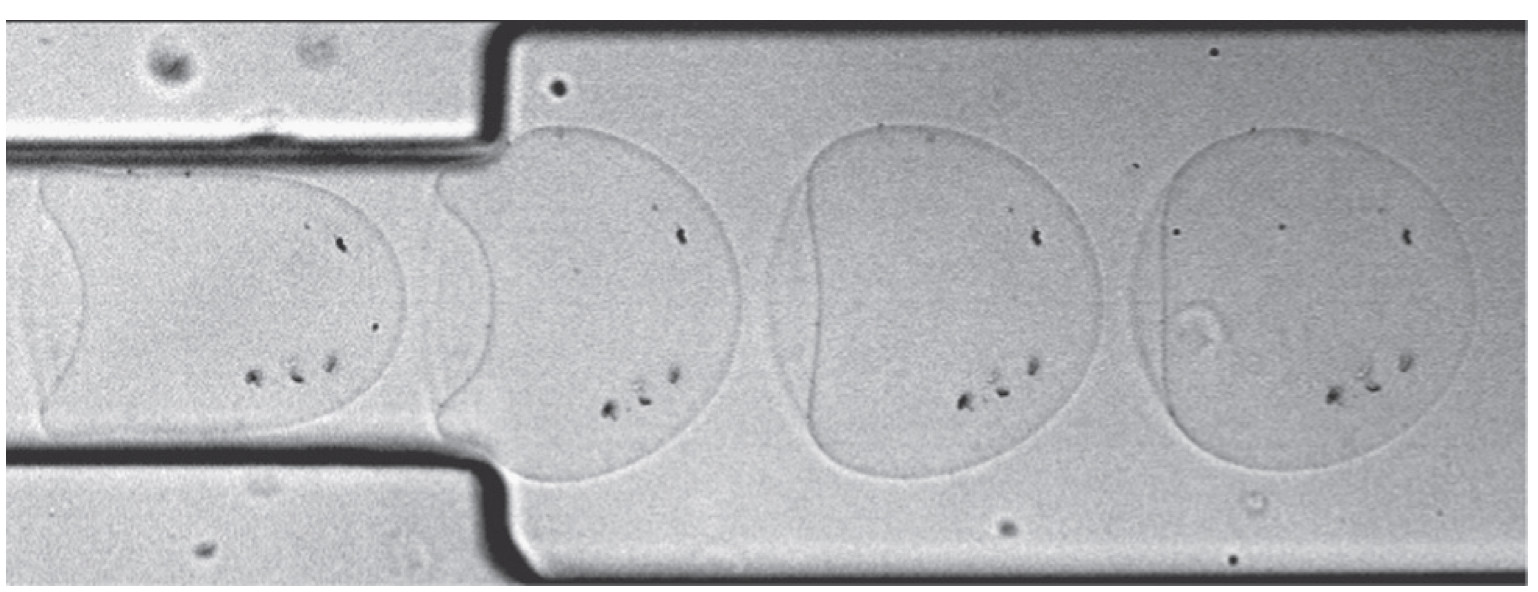

2. Characterization of the viscoelastic properties of capsules

Figure 2: Successive profile of a microcapsule flowing in a microfluidicchannel with a sudden expansion (Gires et al. 2016).

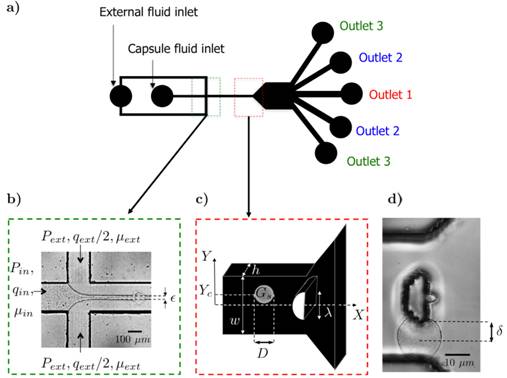

Sorting of microcapsules using microfluidics

Biomedical applications often require sorting cells according to their physical properties, such as size, density or deformability. In recent years, microfluidics has provided a variety of tools to sort micro-objects. We present here a simple microfluidic device (Figure 3) consisting of a channel containing a semi-cylindrical obstacle against which capsules are squeezed by the flow, followed by a diverging chamber where streamlines separate (Vesperini et al. 2017). We demonstrate that this basic system is capable of sorting elastic microcapsules according to their size at low flow strength, and according to the stiffness of their membrane at high flow strength. Contrary to most existing sorting devices, we show that the present one is very sensitive and capable of discriminating between capsules with differences in membrane elasticity of order unity.

Figure 3: Sketch of the experimental microfluidic device, in which the fluids flow from left to right. (a) General view of the sorting device. (b) Photograph of the flow-focusing at the entrance of the straight channel. The capsule suspension is pinched by an external viscous fluid of viscosity μext, and forms a fluid thread of viscosity μin and thickness ε. (c) Dimensions of the obstacle and of the rectangular straight channel. (d) The distance between the center of mass of the capsule and the obstacle is defined as δ (Vesperini et al. 2017)

Collaborators

Dr. Anne Le Goff, BMBI, UTC

Dr. Badr Kaoui, BMBI, UTC

Prof. Dominique Barthès-Biesel, BMBI, UTC

Dr. Eric Leclerc, BMBI, UTC

Dr. Florence Edwards-Lévy, ICMR, Reims

Thi-Xuan Chu, Characterization of the mechanical properties of capsules by inverse analysis, PhD Thesis, UTC, September 2011.

Benjamin Sévénié, Caractérisation mécanique de microcapsules circulant dans un pore microfluidique Master Thesis, Phelma INP Grenoble, September 2012.

Dr. Pierre-Yves Gires, Characterization of the mechanical behavior of HSA microcapsules, Post-doctorate, UTC.

Barbara Carlotta Nosengo, Transient flow of a capsule in a channel with a sudden expansion, Master Project, Politecnico Di Turino (Italy), September 2013.

Yixin Qi, Characterization of microcapsules, Research Project, UTC, February 2014.

Van Tuan Dang, Characterization of the viscoelastic properties of microcapsules, Master Project, UTC, September 2014.

Doriane Vesperini, Sorting of microcapsules using microfluidics,PhD Thesis.

Dr. Adlan Merlo, Microrheology of proteic microcapsules, Post-doctorate, UTC.