Study of the release of the encapsulated medium

Influence of sonication on the release from hydrogel capsules

The objective is to investigate the influence of sonication on the mechanical and release properties of hydrogel capsules (Zhang & Salsac 2012). A new fabrication process is developed to fabricate millimetric capsules made of a highly-viscous liquid core protected by a thin hyperelastic alginate membrane. At high intensities and/or long exposure times, sonication can lead to the capsule rupture, because it induces fatigue in the membrane.

Figure 1: Sonication of hydrogel capsules (Zhang & Salsac 2012).

Below the breakup threshold, no remnant effect of sonication is, however, measured on the capsule mechanical properties. The release is studied by sonicating capsules filled with blue dextran suspended in an aqueous solution. The mass release that results from sonication is found to be proportional to the sonication duration time and pressure wave amplitude. A possible physical interpretation is that the acoustic streaming flow induced by the ultrasonic wave enhances convection in the vicinity of the capsule membrane and thus mass release. We have finally quantified the passive release subsequent to low-intensity sonications: it is on average identical to the one measured on non-sonicated capsules. Overall the membrane therefore recovers its physical and mechanical properties after sonication. If sonication leads to an increase in porosity of the capsule membrane, the increase is temporary and reverses back at the end of the ultrasonic stimulation.

Squeezing bio-capsules into a constriction: deformation till break-up

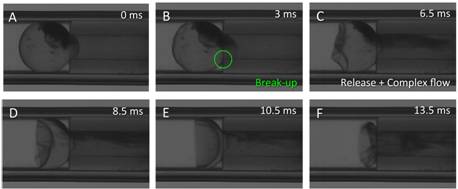

We have studied experimentally the deformation and break-up of liquid-filled capsules trapped at an axisymmetric step constriction, and subjected to increasing pressure drops (Le Goff et al. 2017). We have considered biological (trout fish eggs) and bioartificial (made of ovalbumin and alginate) ones, with the objective to characterize the transition to break-up (Figure 2). We have found that both capsule populations behave as a brittle material. They do not exhibit any plastic deformation prior to break-up. Moreover critical pressure drop exhibits a stochastic behavior as known for the fracture of disordered media. The break-up probability follows a three-parameter Weibull distribution, from which one can deduce the capsule rupture characteristics.

Figure 2: Snapshots of the break-up scenario of a capsule (biological capsule in this case: trout fish egg). The fracture of the membrane typically starts from the corner of the constriction as shown by the circle in (B). Upon capsule break-up, the inner content is rapidly released into the downstream post-constriction tube (C-E). Finally, what remains of the capsule is flushed into the constriction (F) (Le Goff et al. 2017).

Collaborators

Dr. Anne Le Goff, BMBI, UTC

Dr. Badr Kaoui, BMBI, UTC

Liguo Zhang, Ultrasonic stimulation of beads and capsules: measurement of the mechanical properties and increase of

release of encapsulated content, PhD Thesis, UTC, February 2012.

Gaétan Kurzawa, Rupture of capsules in constriction, Master 1 project, 2016.

Boglárka Haszon, Squeezing of capsules under flow, Erasmus project, 2016.