Ergun Software for Bubbling Beds

Fluidization Grid Design

Fluidization grid is one of the most important parts of the fluidized bed. A bad gas distribution may cause a number of problems like gas by-pass and decrease in efficiency. On the other hand, the pressure drop through the grid is not a negligeable cost for the process and is supposed to be held at its lower possible value.

In lab scale pilot a grid may be a simple porous plate with a high pressure drop or a perforated plate with small holes. However, in the industrial practice "tuyeres" are used to distribute the gas uniformly over the bed section. The most important interest of tuyeres is the fact that they are interchangeable when the holes are plugged and they can be changed easily and individually.

Ergun program helps the user to check the design of fluidization grid and its effects on the different aspects of the fluidization.

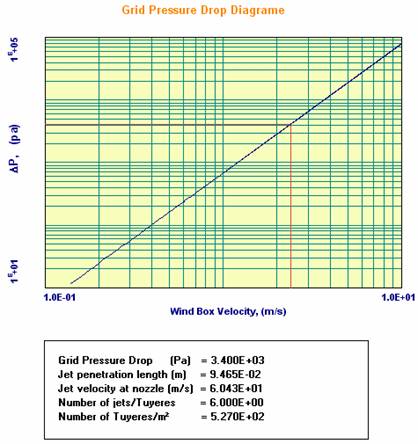

The length of vertical and horizontal jets are calculated and checked by means of Merry's equation. Pressure drop through the grid is checked by the Virtual Expert and in the case of problem, some simple solutions are advised.

Ergun Software offers two possibilities of "Grids" study:

- To calculate how many tuyeres per m² is needed with a given type of tuyere.

- To check the operating conditions for a given number of holes or tuyeres/m².

In any case, a "warning" is generated by the virtual expert if any of "pressure drop", "jet velocity" or "jet length" values are out of limits,.

Ergun Design Technology

Example of tuyeres for grid configuration

example of results as presented in the grid module of Ergun program

Links to other pages: Site Map